Equipped with state of art machines, and placing strategically near customer we are working on JIT system to maximize the returns of investment.

We have following units

-Plot No.93-94,HSIDC, Sector-59, Ballabhgarh, Faridabad. 121004, Haryana.

- Having built up area- 35000 sq.ft.

- Working Strength- 155 nos.

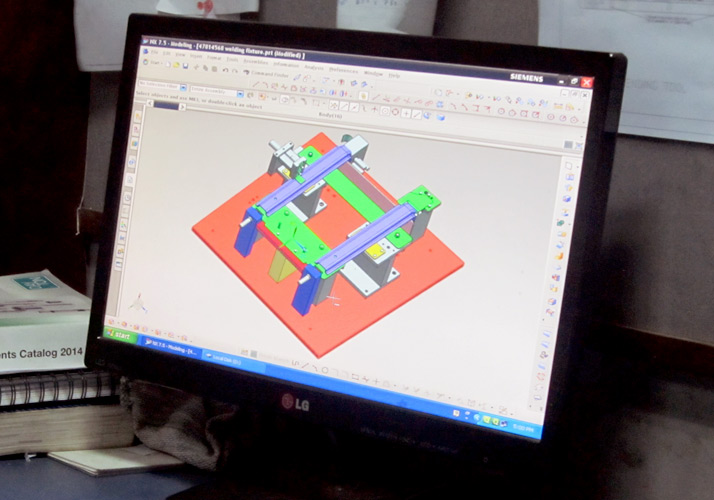

- Facilities- Press Shop, Weld Shop, Tool Room, R&D, Training Hall.

- Customers- India Sub-continent JCB, CNH(Fiat), Tafe (Eicher) -Overseas- JCB(UK), Bomag(Germany), Terex(UK).

-Plot No.35, HUDA, Sector-59, Ballabhgarh, Faridabad 121004, Haryana.

- Having built up area -15000 sq.ft.

- Working Strength- 122 nos.

- Facilities- CNC Turret Punching Press, CNC Brake Press, CNC Pipe bending, PLC controlled Fully Automatic Surface treatment plant, Conveyorized Powder Coating Plant

- Customers- Ancillary to Unit-I, Ashok Leyland, Tata Marcopolo.

-Plot No.158D, KIADB, Belur Industrial Area, Dharwad, Karnataka.

- Having area -83000 sq.ft.

- Working Strength- 100 nos.

- Facilities- CNC Turret Punching Press, CNC Brake Press, CNC Pipe bending, Surface treatment plant, Powder Coating and Paint.

- Customers- Tata Marcopolo, Sivaco(Canada), Heico(USA)

Plot No. 52, HUDA, Sector-59, Ballabhgarh, Faridabad 121004, Haryana.

- Having area -43000 sq ft.

- Facilities- CNC 5-Axis Pipe bending Machine, 500 T Pneumatic Press, Angular Pipe cutting machine, Amada Laser Cutting

- Weld Shop for Medium Fabrication